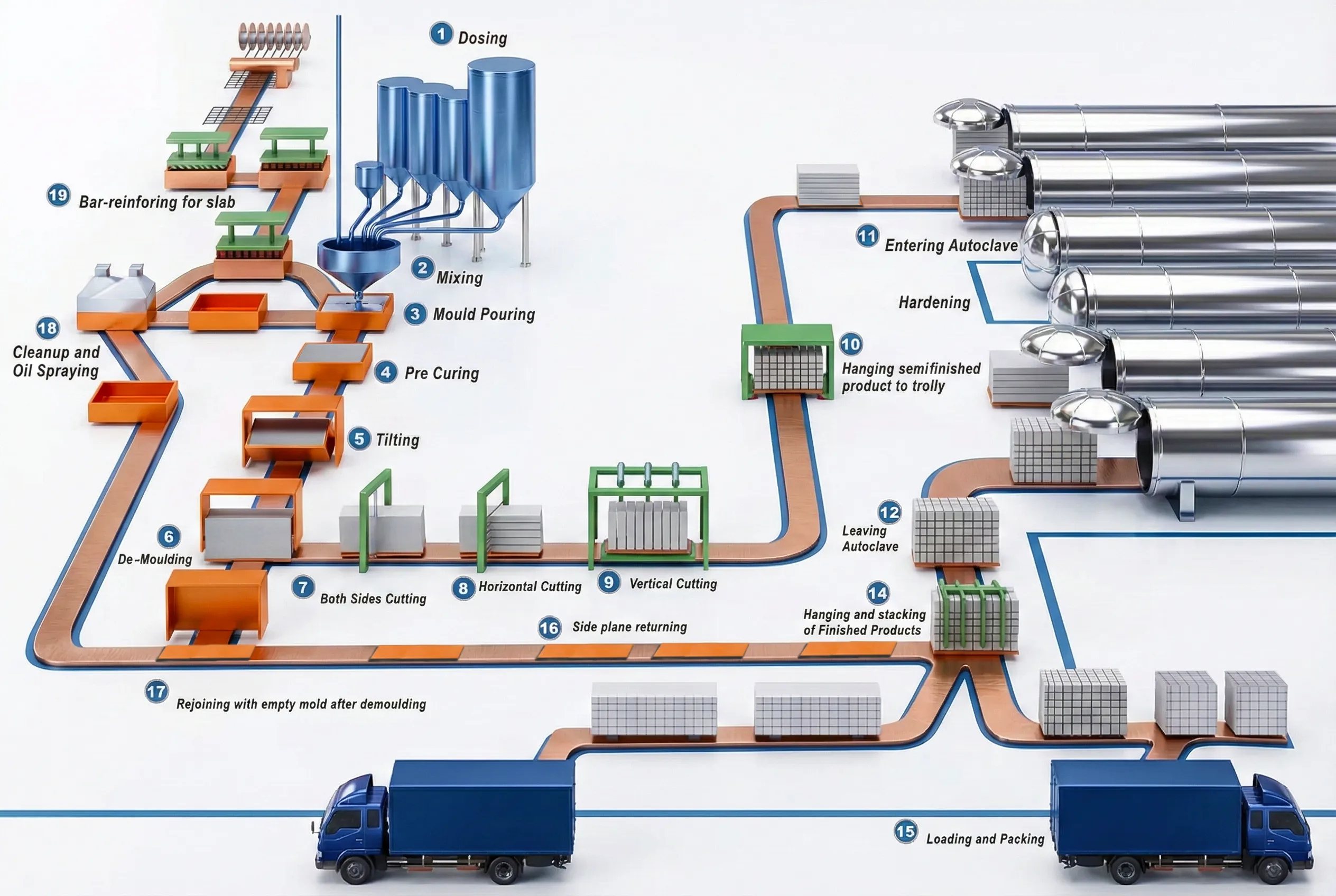

Raw Material Preparation:

The first step in the manufacturing process of AAC blocks is the preparation of the raw materials. The materials used in the process are cement, lime, fly ash, gypsum, water, and a small amount of aluminium powder. The raw materials are mixed in the right proportions using a mixing machine.