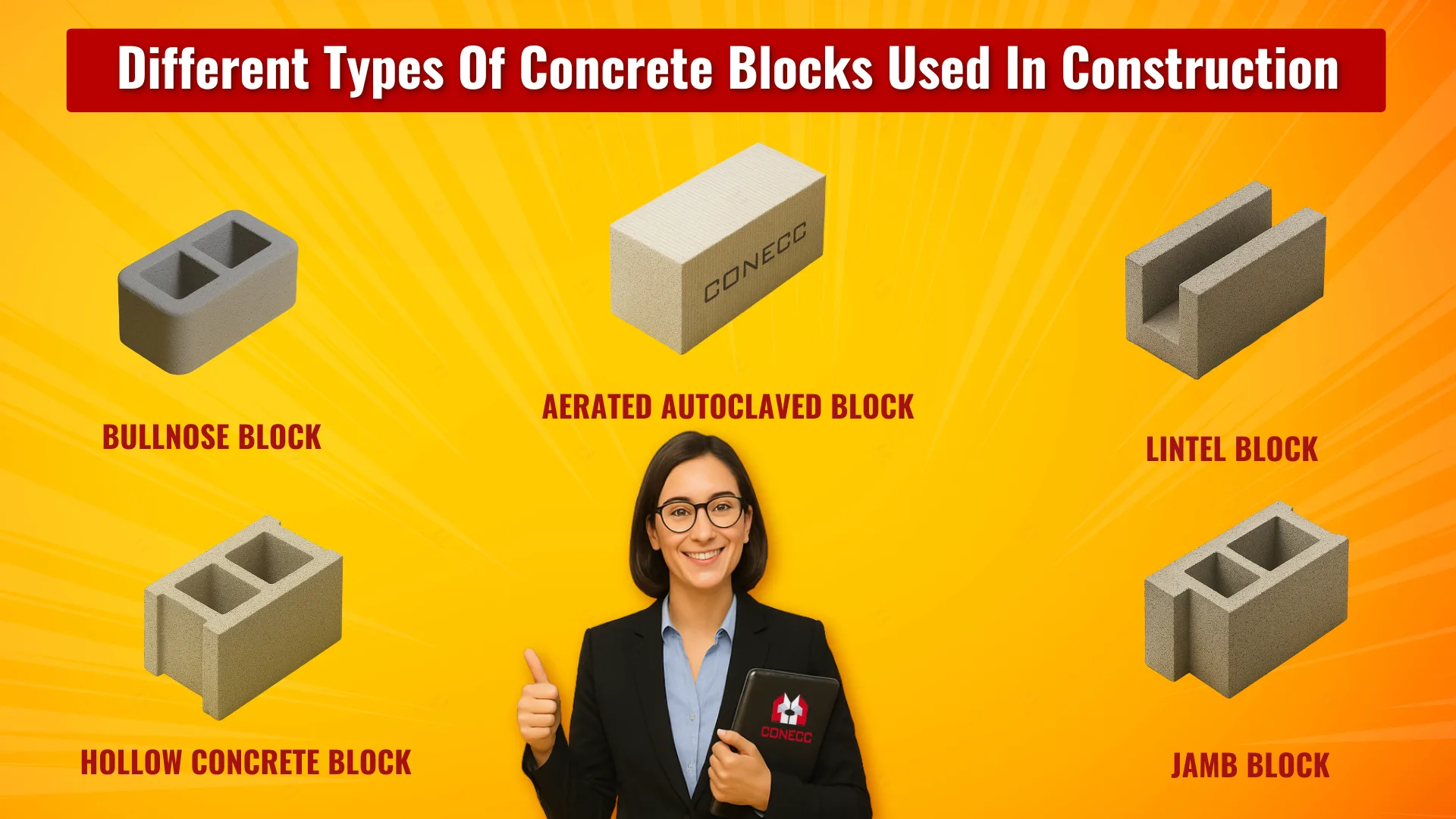

Different Types Of Concrete Blocks That Are Used In Construction

Concrete Blocks That Are Used In Construction

Concrete blocks can be classified into two main types hollow and solid. These two varieties of concrete blocks can be utilised for a variety of tasks in addition to wall construction. As you’ll see, not every solid concrete blocks are completely solid, but they are more solid than hollow concrete blocks. Below, we’ll go into more detail about the many varieties of concrete blocks, often called as CMU or concrete masonry units.

Concrete and cement are also frequently used interchangeably. Concrete is created using cement as a component. About three 3 parts out of 4 of what we find in concrete are other materials, like sand, gravel, and stone. Concrete is made by mixing water and cement, a powder made of limestone, clay, and other materials, into the mixture.

The formation of a type of naturally occurring cement from the interactions of limestone and oil shale actually marks the beginning of the history of concrete. It is believed to have been found for the first time in what is now Israel and dates back roughly 12 million years. Everything from the Roman Colosseum to the Chinese Great Wall was constructed with cement.

An alternative to brickwork in construction, concrete blocks have both benefits and drawbacks. Concrete blocks are larger than bricks, thus the mortar joints holding them together need less cement to keep them together. However, concrete blocks are more likely to slide and crack when the foundation shifts than bricks due to their higher moisture content and greater size.

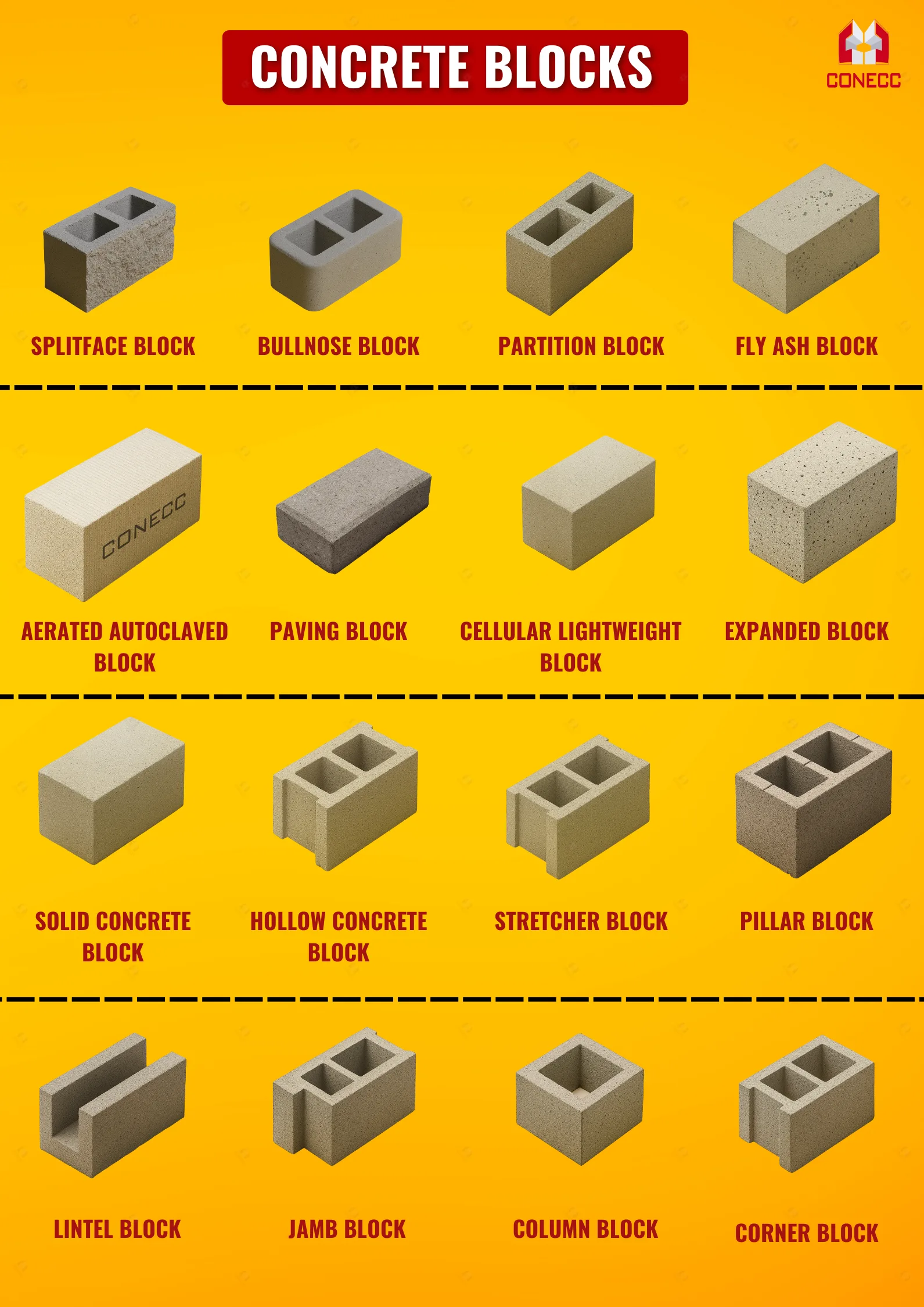

Solid Concrete Blocks vs Hollow Concrete Blocks

Concrete blocks come in hollow and solid varieties, which are the two most common types used in construction. Fully solid blocks are frequently utilised for paving operations and other tasks requiring stability and endurance. You would never want to attempt to walk on flooring with holes in it.

When creating boundary walls and other huge buildings, hollow blocks are employed, which have holes that occupy more than one-quarter (typically more than half) of its cross-sectional area. They are lighter thanks to the holes, which can be advantageous when wiring or running pipes through them. For extra stability, you may also put rebar through the holes.

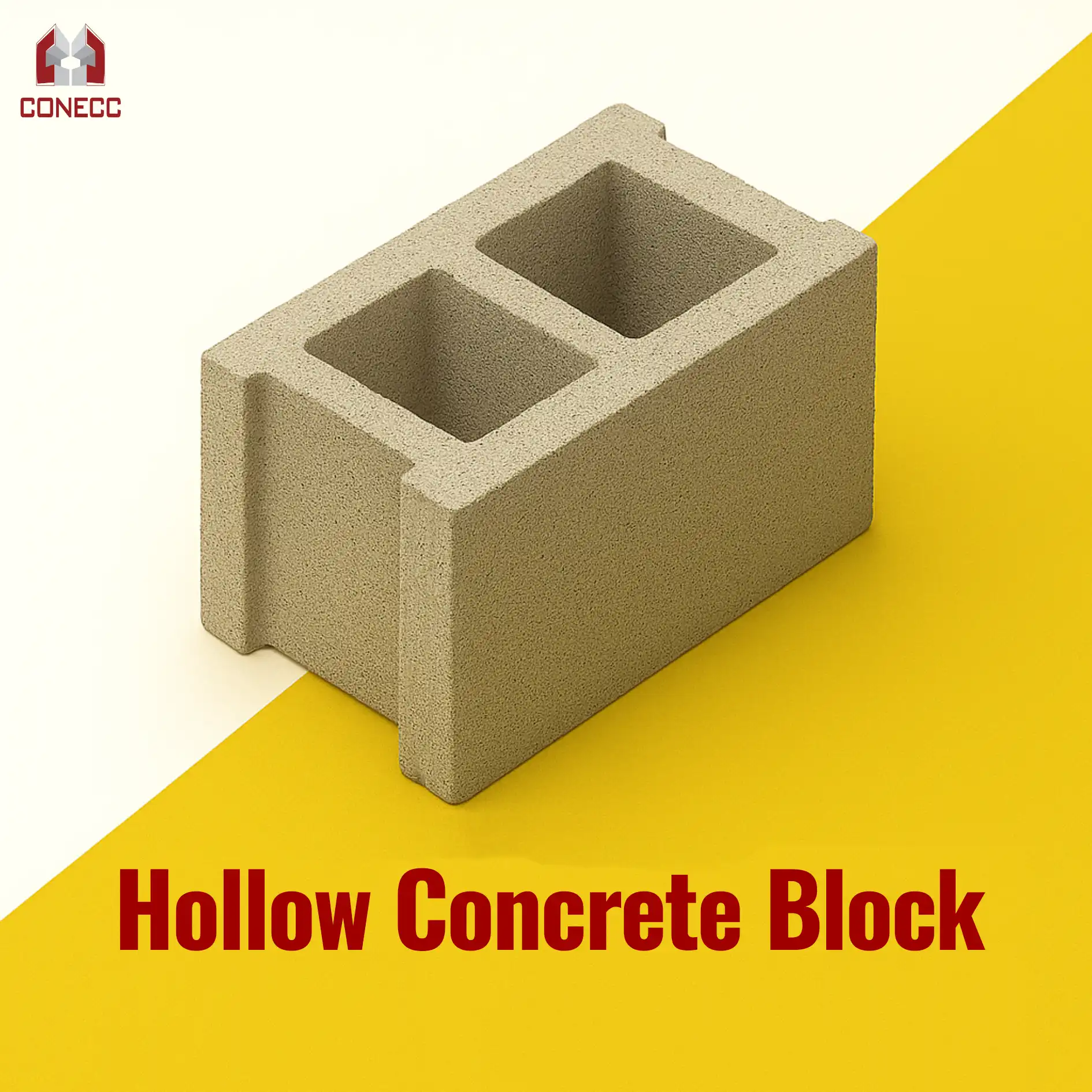

Hollow Concrete Blocks

There are three grades of hollow concrete blocks, with Grade A having a minimum density of 1,500 kg/m3. The density for Grade B is less than 1,500 kg/m3. The density of grade C is larger than 1,000 kg/m3. For load-bearing concrete block walls, grades A and B are employed, whilst grade C is utilized for non-load-bearing walls.

Solid Concrete Blocks

Fully solid concrete blocks have the appearance of grey bricks but are typically larger. They’re useful for building walls that protect against the elements, such as strong winds. They are also suitable for garden walls and planters, retaining walls, foundations, steps, and firepits. Although solid concrete blocks are typically heavier than hollow concrete blocks, they can be less expensive.

Hollow Concrete Blocks Types

Hollow concrete blocks are available in several sizes, including 100 mm x 200 mm x 400 mm, 150 mm x 200 mm x 400 mm, and 200 mm x 200 mm x 400 mm. These blocks are most commonly grey, but they can also be found in other colours such as tan and dark red. Here are a few of your alternatives.

Stretcher Block

Concrete stretcher blocks are used in building projects to connect masonry unit corners. Their faces are parallel to the wall’s face.

Pillar Block

Pillar blocks, as the name implies, are commonly used to construct pillars or piers. They are also known as double-corner blocks and are designed to have both ends visible. Many people envision pillar blocks when they think of concrete blocks, and they are frequently available in large quantities at building supply stores.

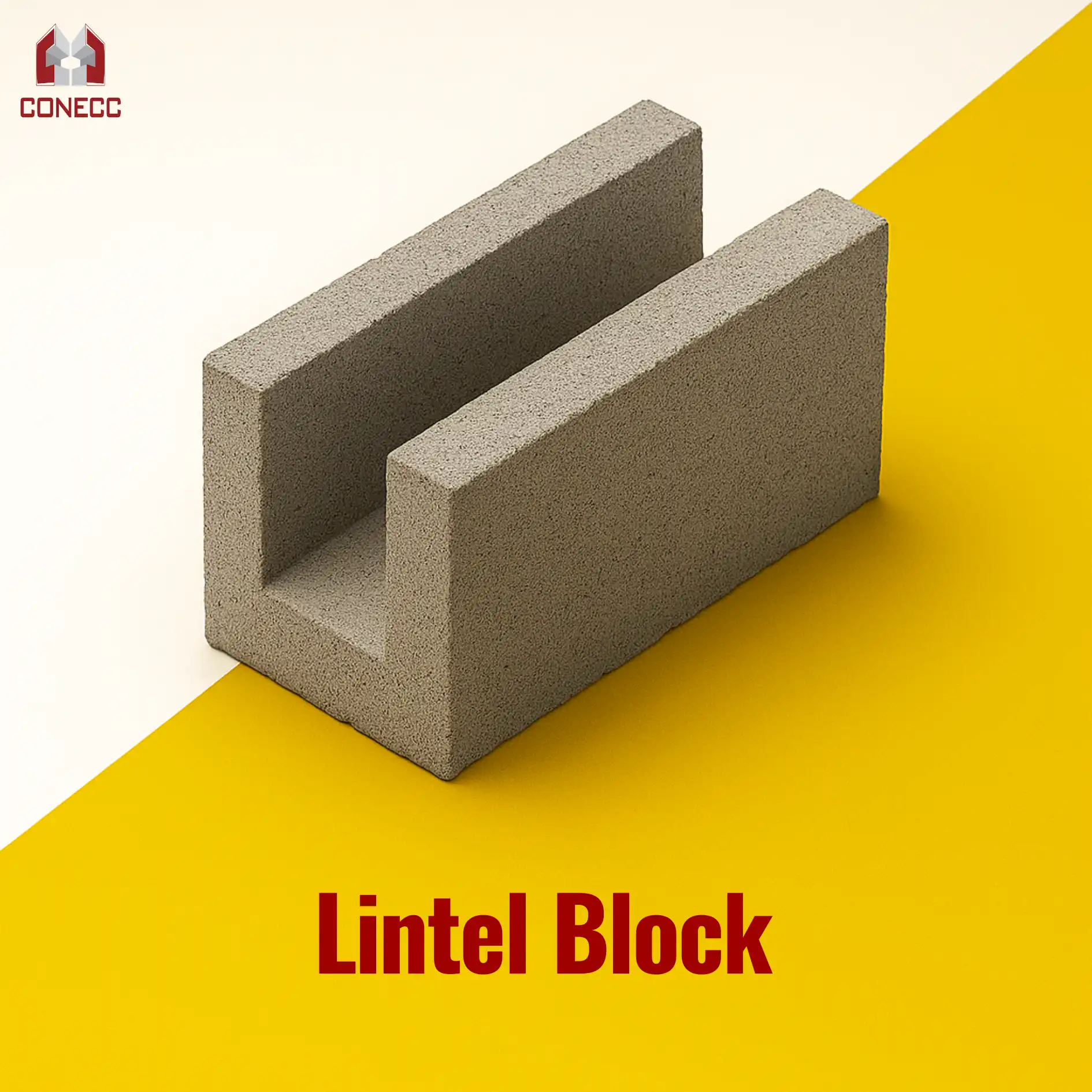

Lintel Block

Lintel blocks, also known as channelled or beam blocks, are distinguished by their U shape. The U shape’s deep grooves, which run the length of these blocks, are filled with concrete and reinforcing bars. They’re typically used on the tops of doors and windows to transfer the load pressing down from above in preparation for lintel beams. A solid-bottom lintel block, such as the one shown here, is available in 6-by-8-by-16-inch sizes.

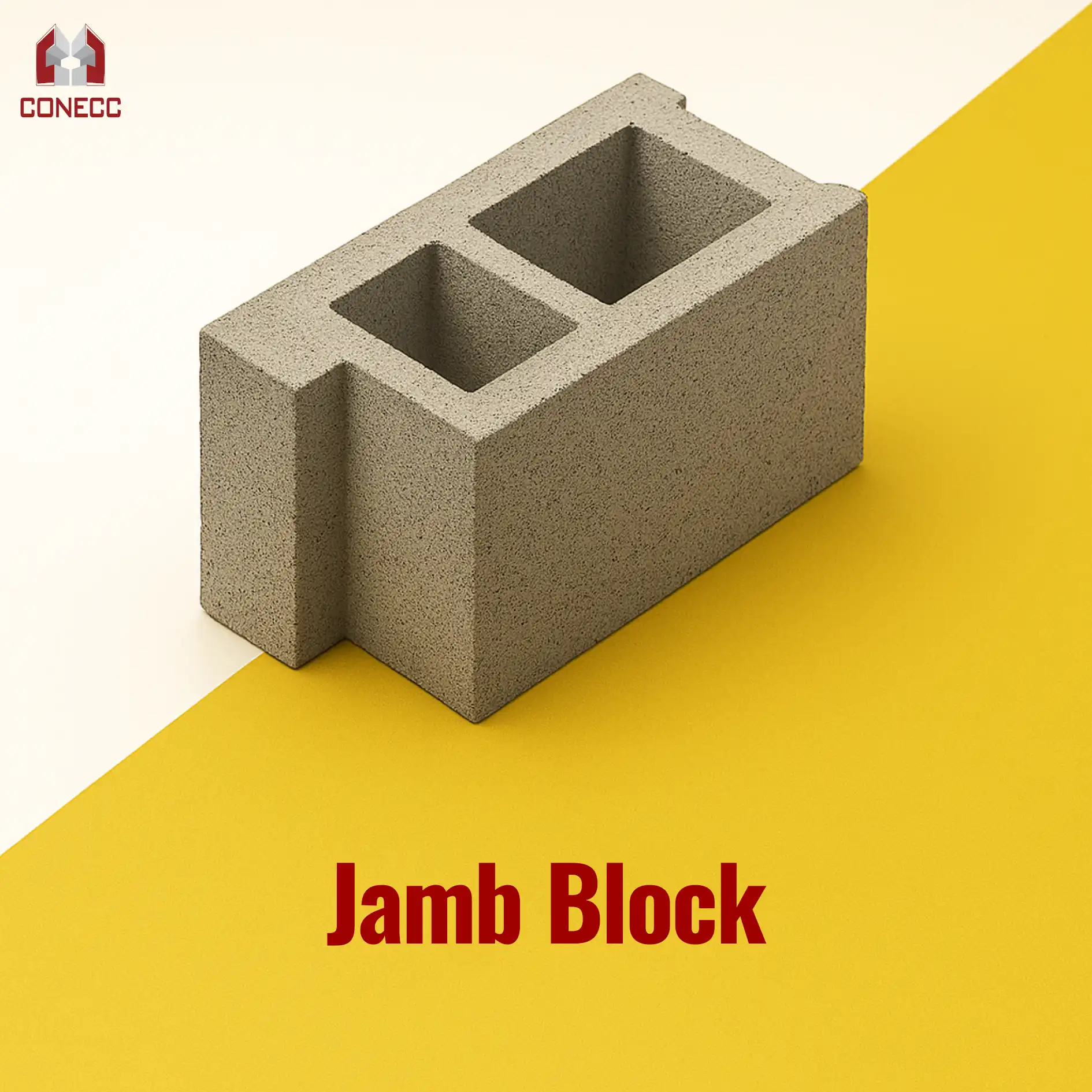

Jamb Block

Jamb blocks have a shallow groove that runs across the two holes and a deeper groove at one end. They provide space for a window’s casing members and are commonly used in double-hung windows.

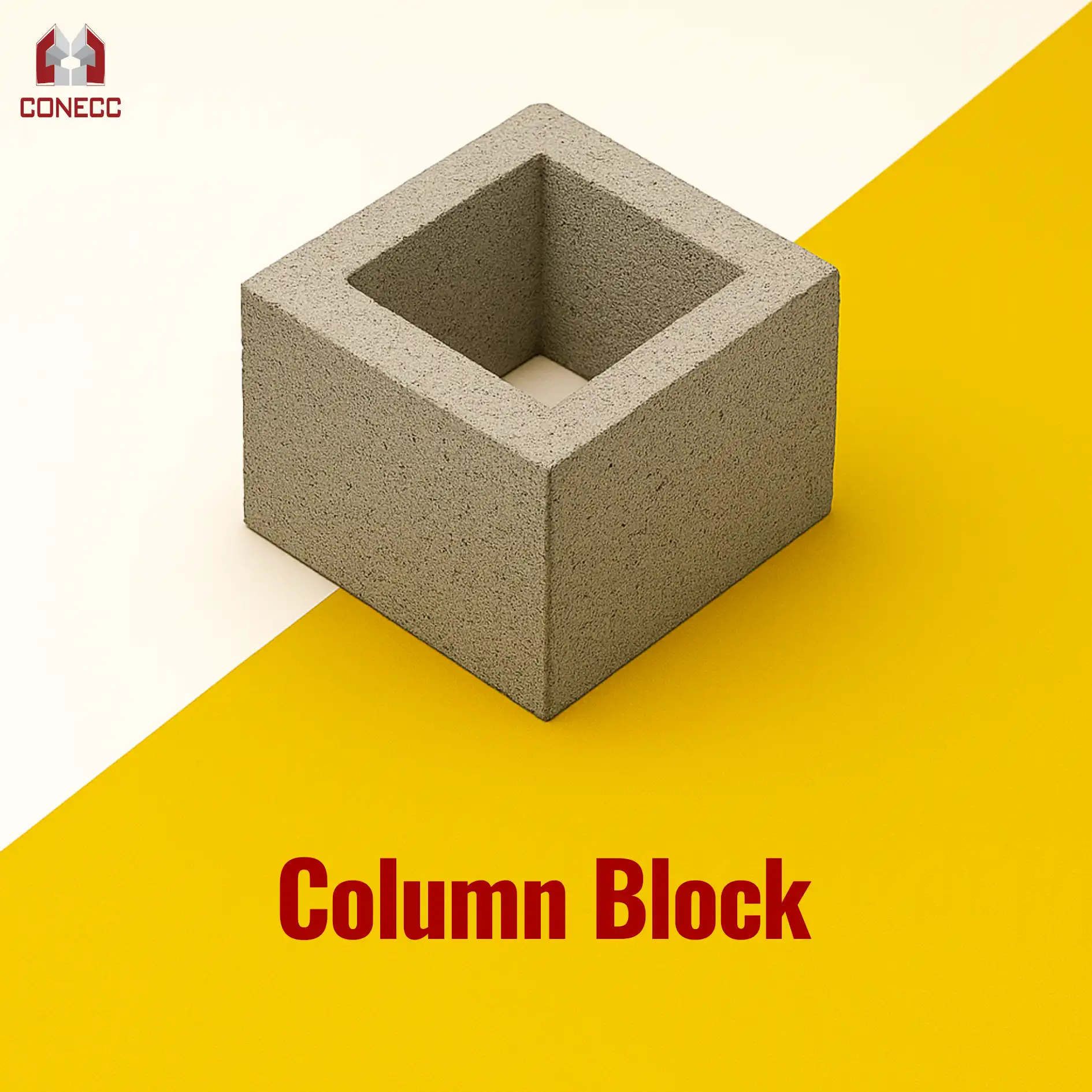

Column Block

Typically, a column block is a square block with a single hole. These can be stacked to form columns and reinforced on the inside.

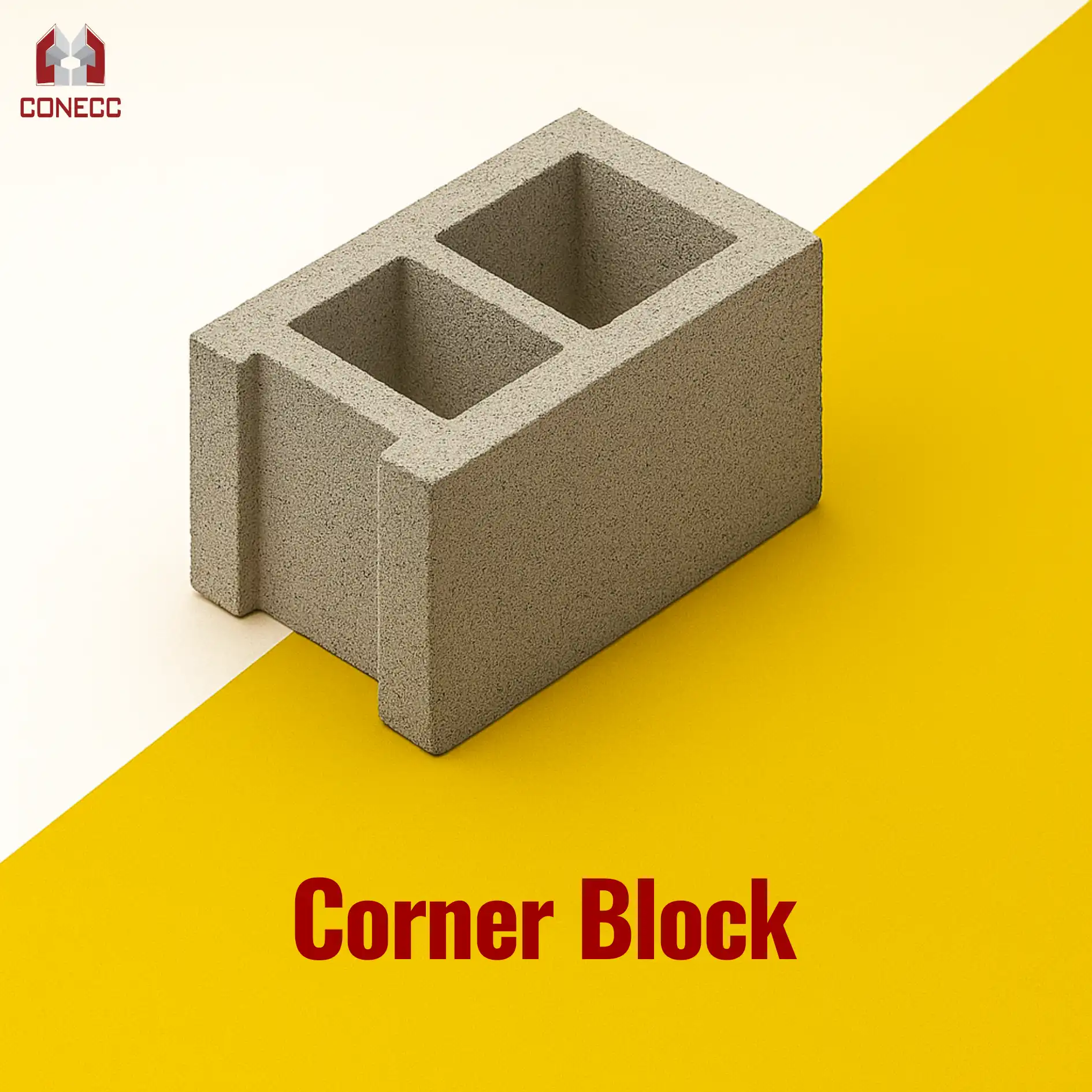

Corner Block

Corner blocks are typically used at corners or at the ends of window and door openings. The stretcher side runs parallel to the wall, while the plain side is exposed to the outside.

Splitface Block

Splitface blocks are similar to pillar blocks, except that one edge has a very rough, almost jagged texture that reveals the block’s inner aggregates. This block is porous and thus susceptible to water damage, but it also has a lower risk of termite infestation and is less flammable. A splitface block like the one shown above could be 6-by-8-by-16-inch in size.

Bullnose Block

Bullnose blocks have the same use and structure as corner blocks, but they have rounded edges (which is the reason for their name). A single bullnose block, such as the one shown here, may be available in a 6-by-8-by-16-inch size; a block with a double bullnose at one end may also be available in the same size.

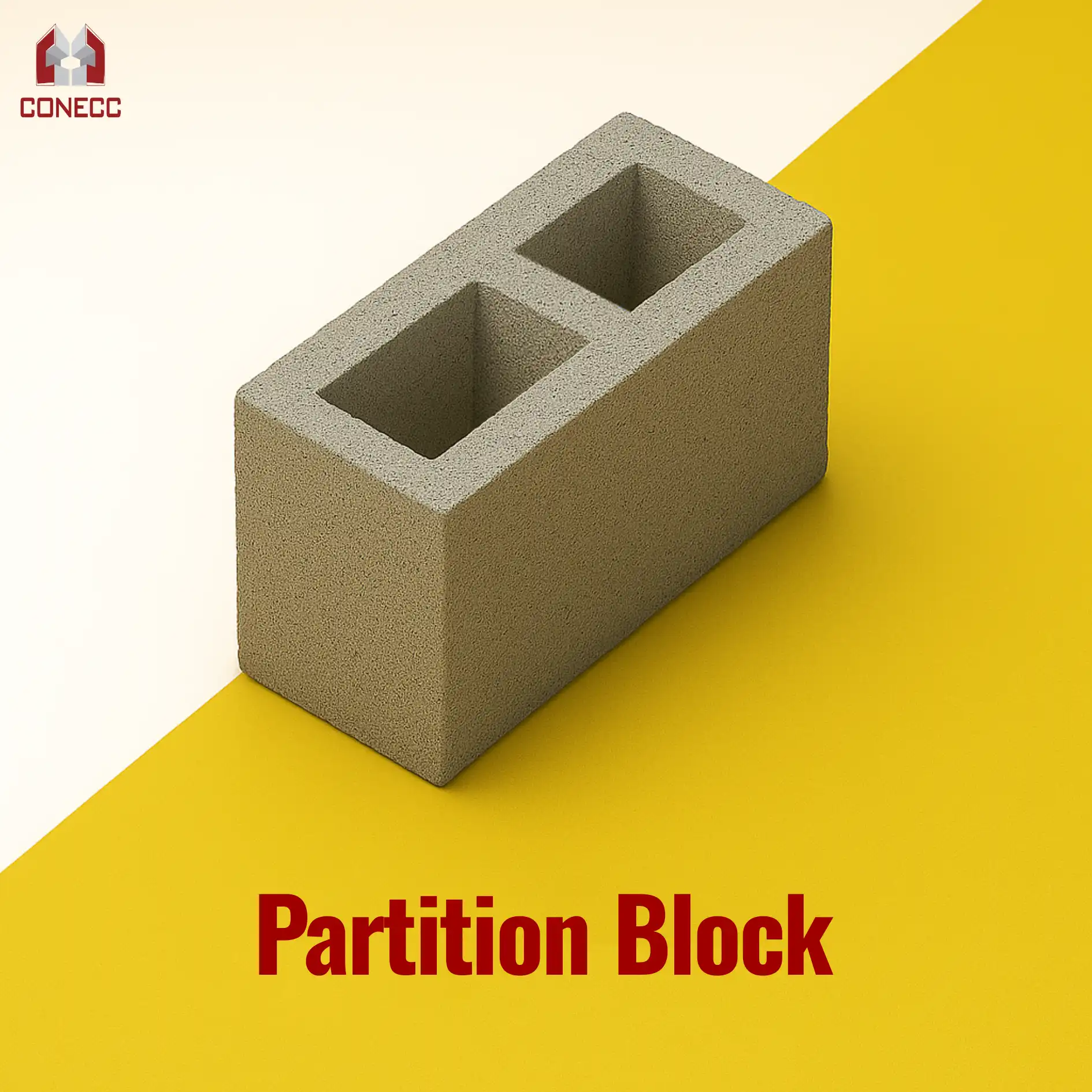

Partition Block

Partition blocks look similar to concrete pillar blocks but are taller than they are wide. When viewed straight on, these narrow blocks resemble wide goggles.

Solid Concrete Blocks Type

When it comes to solid concrete blocks, your options will be less diverse than when it comes to hollow concrete blocks, but you will still have a variety to choose from that can be used for a variety of purposes.

Fly Ash Block

Fly ash is a fine, powdery substance that, when mixed with water, produces a material similar to Portland cement. (Portland cement is made by combining finely ground or burned limestone with clay or shale.) Fly ash is used in more than half of the concrete placed in the United States. Fly ash can be used in place of cement concrete in road projects that require a large amount of material.

Fly ash is classified into two types:

- Class C is a high-calcium variety with less than 2% carbon. It can make up 15% to 40% of the cement material.

- Class F is a low-calcium material with a carbon content of 5% to 10%. It typically accounts for 15% to 25% of the cement material.

Using fly ash can reduce CO2 emissions, provide cold weather resistance, and reduce cracking and permeability. It can also be used to create a smooth, detailed surface. Like Portland cement, fly ash is a fine powder that can be used as a pigment. The colours of the particles can be amber, brown, grey, green, olive, red, yellow, or yellow-brown. The resulting colour can vary depending on particle concentration, but it is usually a shade of grey. Fly ash bricks are typically only available in small sizes because they become less durable as they grow larger and are more prone to fractures and cracking.

Aerated Autoclaved Block

Aerated autoclaved block, or AAC block for short, is a lightweight material with excellent sound and temperature insulation. Although it is not as widely available as other types of concrete, its fire resistance and insulating properties make it an appealing choice.

The name “aerated” refers to the fact that these lightweight concrete blocks are 80% air. The material is easily shaped and can be used with nails and screws and it is as strong as other blocks.

These white to light grey blocks can be tailored for use in sidewalls, partition walls, and other types of wall construction, as well as steel pillars and infill panels. They come in blocks, panels, and speciality shapes like lintel blocks and U-shaped bond beam blocks, both of which come in a variety of thicknesses. Conecc AAC blocks produce the best quality AAC blocks in India. Conecc AAC blocks are lightweight and strong. Also provides thermal insulation, fire resistance, pest resistance, moisture resistance etc.

Paving Block

Paving blocks are solid square or rectangular blocks that are used for paving, road shoulders (which should be painted to improve visibility), and walkways. Although they are commonly brick-shaped, they come in a wide range of sizes and colours, including sandstone, tan, dark brown, charcoal, and light grey.

Cellular Lightweight Block

Cellular lightweight block is a construction material made up of three components: foam, fly ash, and cement. It, like AAC, provides excellent sound and temperature insulation. It is fire-resistant, environmentally friendly, and reasonably priced. These light grey blocks are made of a material that dates back to the 1930s. They can be made in a variety of sizes and used for wall panels, compound walls, and parapet walls. High-density cellular lightweight blocks are appropriate for load-bearing or partitioning walls, while medium densities are appropriate for non-load-bearing brickwork.

Expanded Clay Aggregate Block

Expanded clay aggregate blocks are made of lightweight fly ash and cement aggregates. Because they are waterproof and fire-resistant, as well as lightweight, they can reduce the overall structural load by up to 50%. They also provide good sound and temperature insulation. Because this material is fired in a kiln, it can be moulded into various sizes and densities.

Conclusion

Concrete blocks can be useful components in a variety of construction projects, such as laying down a roadway, constructing load-bearing masonry walls, or constructing partition walls.

To choose the right product, consider how you’ll use it and the properties you want to highlight. Different types of concrete blocks are intended for use in specific areas of a structure, such as over windows or at corners. Some require more reinforcement than others, and some provide better thermal and sound insulation than others.

Do you prefer a dense aggregate or a lighter alternative? Another important factor to consider is cost. How much money do you have? After you’ve answered these questions, you’ll be in a better position to select the appropriate equipment and start your construction project. And you’ll have more confidence that it’ll be safe and done correctly the first time. AAC Blocks are eco-friendly alternatives for normal concrete blocks. If it is available in your area it is the best choice because these are lightweight, durable, fire resistant, moisture resistant, pest resistant and inert. These will stand strong for generations.

| RELATED TOPICS |

|---|

| aac blocks online |

| aac blocks sizes and prices |

| aac blocks disadvantages |

| aac blocks near me |

| aac blocks advantages and disadvantages |

| aac blocks price |

| aac blocks manufacturers |

| aac block price near me |

Recent Posts

Universal AAC Block Calculator

Plan your construction project with precision using our Universal AAC Block Calculator....

Read MoreWhat Is Woven Wire Mesh?

Hey, if you're working on any project, woven wire mesh is basically...

Read MoreTop 10 FAQs About AAC Blocks Answered by Experts

Discover the innovative world of AAC blocks—Autoclaved Aerated Concrete blocks that are...

Read More